REM’s projects are always group projects: the professionalism of an experienced and qualified team, with long and proven experience, will involve you, step by step, in the mechanical, pneumatic, electrical and electronics integrated design in order to implement an ad-hoc system specifically tailored to your production requirements.

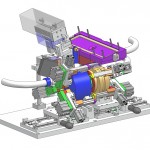

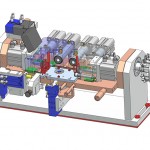

The carefully customised system is fully manufactured at our premises, where the mechanics of the assembly and testing stations, the electric, pneumatic and hydraulic hardware, are specially designed according to the characteristics of your production and of each component to be tested.

The system software, produced according to the functional needs of the system designed, is managed through dedicated technology, including:

- PLC with operator panels

- Integrated PC touch

- Structure layout of the circuits and the descriptive phases of the process

- Management parameters of the system and of the analogic and digital variables

- Set up of the instruments present on the work-station

- Setting of test parameters for each individual piece produced

- Supervision via remote cameras, for better maintenance management

The final test of the system is carried out by specific and qualified technicians and aims at verifying, with accuracy and precision, the production capacity of the system, in order to ensure the full operational efficiency according to the goals set during the design phase.