THE ULTIMATE DATA ACQUISITION

REM designs and manufactures systems for the analysis, monitoring and control of vibrational tests, both in production and in laboratory, according to the specific customer requirements and using the best technology available on the market.

Below are some of our products.

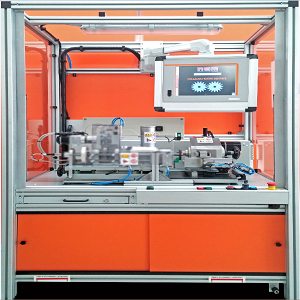

Testing equipment for detection and analysis of cracks, in wheels’ profiles. This machine indicates the angular position of the defect through a special marker. Such machine performs a specific vibrational analysis, carried out through a software that we have developed, for each type of product to be tested. The range of toothed wheels analyzed is characterized by an outside diameter between 30 and 200 mm, divided into 16 types of product. The test data (Product code, batch, test result, date, time) are stored in a local database, accessed from both the machine itself or remotely.

Testing equipment having the function of verifying the opening and closing of a solenoid valve by monitoring the vibrations of two electromagnets. This test is performed using piezoelectric technology. In addition, it can also verify the presence of filter, screws, ground pin, leak and electrical tests.

Testing equipment having the function of verifying the opening and closing of a solenoid valve by monitoring the vibrations of two electromagnets with oil bath nucleus. This test is carried out with piezoelectric technology.

In addition, it can also verify the presence of filter, screws, ground pin, leak and electrical tests.

In addition, it can also verify the presence of filter, screws, ground pin, leak and electrical tests.